Soulé Software is proud of not only our 35+ year company history but also of our legacy in the industry that spans back 110 years.

Edward Soule, a graduate of UC Berkeley, begins to work as an engineer for John B Leonard in San Francisco.

Edward Soule witnesses the devastation of the San Francisco earthquake. Prior to the disaster, the city had primarily been built with unreinforced masonry and wood frame construction.

John B Leonard, Edward Soule's boss, is among a select group of engineers with previous experience using reinforcing steel in construction.

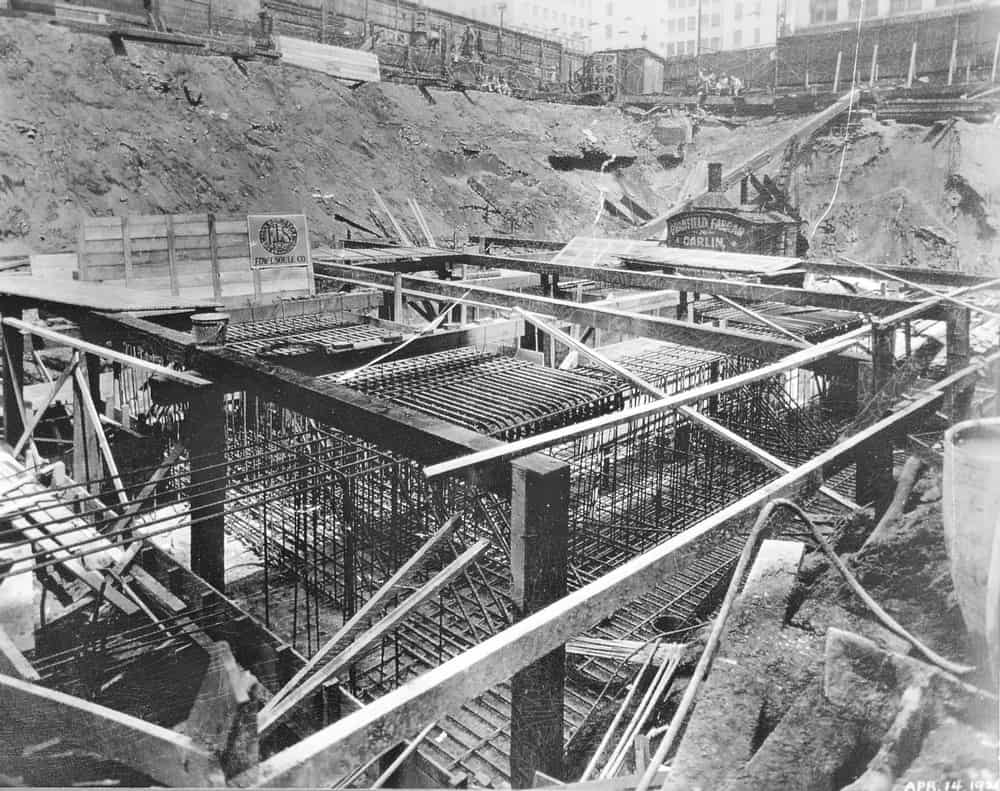

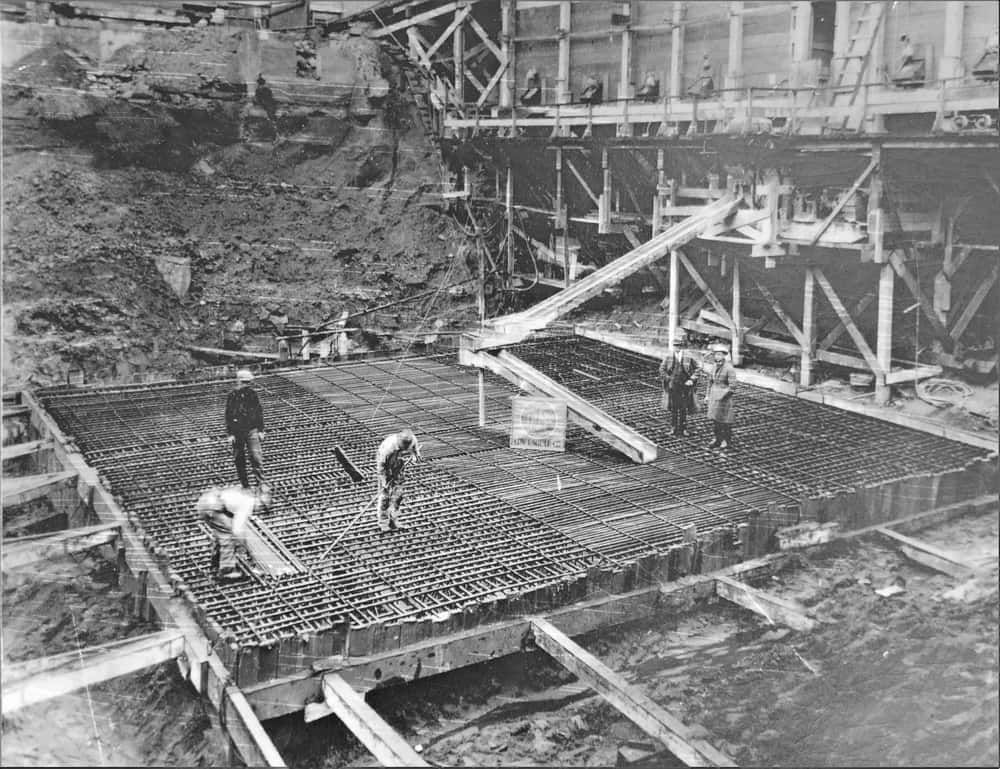

Soule learns how to oversee the placement of reinforcing bars (aka "rebar") during construction.

Edward begins taking on jobs independent of John B Leonard, unofficially starting the Edward L Soule Company.

He rents a lot between 3rd & 4th Street, establishing an office with two assistants for engineering projects.

His first awarded job is the Pacific Coast Syrup Company.

The business earns nearly $16,000.00 in its first year.

Edward begins taking on jobs independent of John B Leonard, unofficially starting the Edward L Soule Company.

Edward L Soule Company, a single proprietorship, is officially formed.

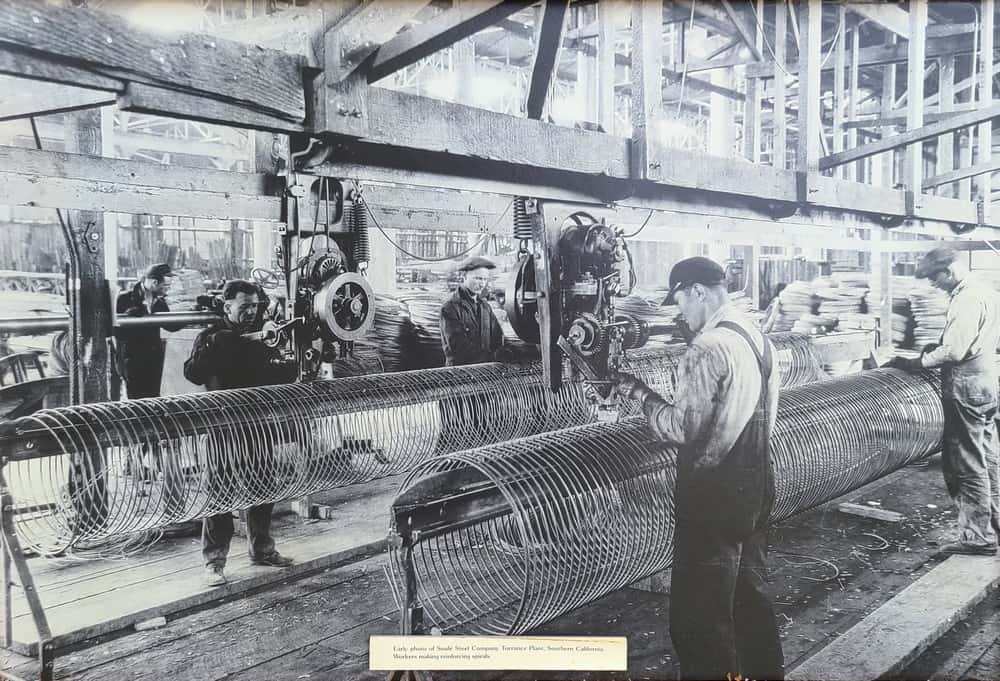

The company begins taking contracts for field placement of reinforcing bars.

Shortly afterward, the company purchases secondhand equipment to start fabricating some of its own rebar.

Edward L Soule Company becomes one of the first companies to combine the fabrication & placing of reinforcing steel in a single contract within the United States.

The company is awarded contracts from Eureka, CA to San Jose, CA (including the San Francisco Bay Area).

While America is engaged in World War I, the company starts to receive large orders to export steel, requiring additional export managers and salespeople.

By 1920, the Edward L Soule Company sells over $1 million of steel, primarily to Asia.

The Edward L Soule Company purchases the American System of Reinforcing, which begins Soule’s 90+ year history in the Southern California region.

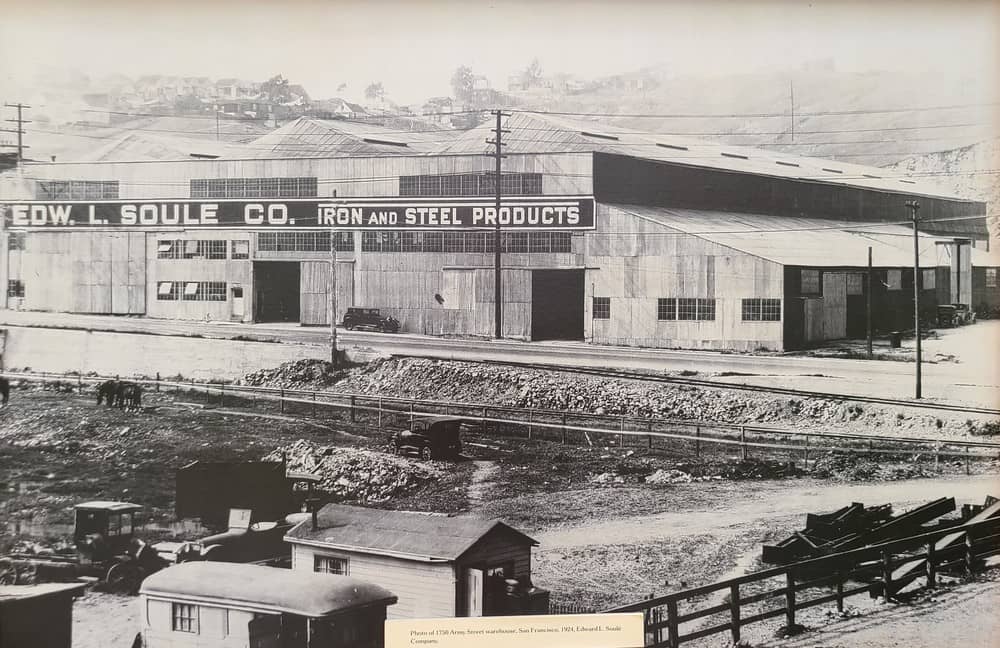

The company moves the San Francisco operations to a larger facility at 1750 Army St.

The Soule Steel Company is formed from the merger of the Edward L Soule Company, the American System of Reinforcing, and the Concrete Engineering Company of California.

Edward also buys the controlling interest of the Concrete Engineering Company of Omaha.

The Soule Steel Company builds an office and a plant in Portland, Oregon to further expand the business. In opening the new branch, Soule becomes a major player in the West Coast Steel market, not just limited to California.

To overcome the financial struggles of the Great Depression, Soule introduces his version of the all-steel house at the 1939 World’s Fair in San Francisco. It is a massive success.

The Navy, needing landing crafts for the troops fighting in the Pacific Theater, selects the Soule Steel Company to build the LCM’s (Landing Craft Mechanized) or “Elsie-M’s”, as the workers dub them.

By 1942, all three of the Los Angeles, San Francisco, & Portland plants are rolling out Naval crafts, resulting in the company growing to more than 1,200 employees.

In 1944, the Soule Equipment Company is created to distribute & service LeTourneau heavy-moving equipment produced in Northern California. It later grows into one of the largest companies of its kind in the nation.

To better serve its growing customer base, the Soule Steel Company opens a steel mini-mill in Carson, CA. The mill achieves 100,000 tons of annual production.

Branch offices are opened across the United States in:

The company continues to expand into new markets by opening offices in:

The Soule Steel Company’s block logo with triangles top and bottom is first introduced.

1961 – The Company Celebrates Its 50th Anniversary

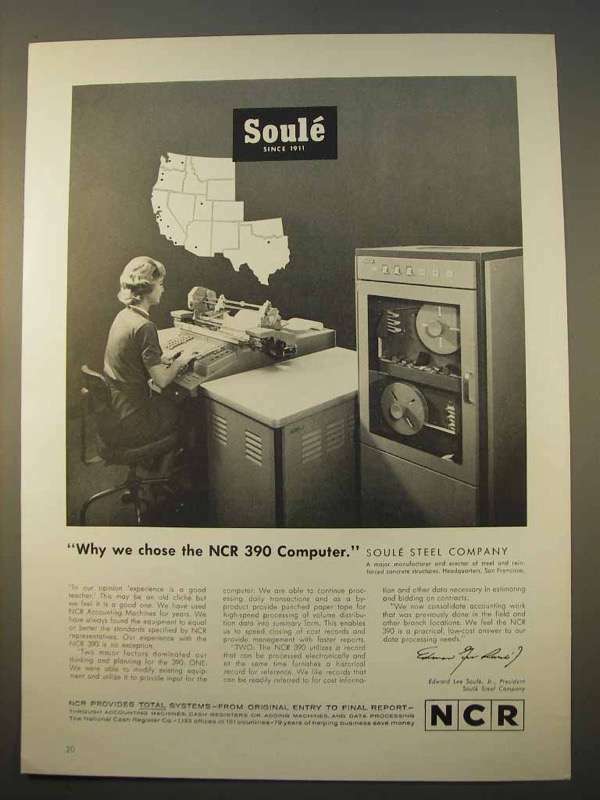

Soule Steel Company now:

Two days before his 89th birthday, Edward passes away.

His three sons (Howard, Lee, and Stanley), having been involved in the leadership of the business for years, continue to lead the company with the culture and values that Edward had embodied.

Soule Steel Company introduces multiple new products and services, cementing its place as one of the leading steel companies of the Western United States. Despite inflation and the high cost of scrap steel, profits more than triple in the 1970’s.

A global recession and numerous other factors lead to the closure of the Soule Steel Company:

Leveraging his rebar industry and software experience from Soule Steel, Sandy Soule starts the Soule Teleprocessing Corporation just north of Silicon Valley in Northern California.

The initial customers in Southern California have dedicated data line connections to the mainframe computer system which is housed in a raised floor, air-conditioned room in San Ramon, CA.

Rotating nightly data backups are done on tape drives, storing an "impressive" 64Mb per tape.

Soule Teleprocessing introduces standalone Estimating, Detailing, and Tagging programs that are designed to run on the newly available personal computers (PCs).

At first, the programs are MS-DOS based, later rewritten for the new Microsoft Windows 3.1 platform.

Sandy's son, Kevin, graduates from UCLA with an undergraduate degree in engineering and begins working full-time at Soule Teleprocessing in January of 1996.

After being introduced to computer programming in the third grade, Kevin studied computer science through junior high and high school.

During his summers in high school and college, Kevin worked on developing many of the software modules for Soule Teleprocessing and answered telephone support questions from customers.

Soule Teleprocessing begins attending the World of Concrete tradeshow and is introduced to a multi-plant East coast fabricator who has been searching for a complete rebar software solution.

With looming Y2K software concerns, many companies like Barker Steel Company have spent the last few years searching for a comprehensive rebar software package to address their estimating, detailing, and tagging needs, while also tracking their business flow from sales to accounting.

Soule Teleprocesssing begins developing a new package that incorporates their Estimating, Detailing, and Tagging modules with their mainframe-based VAX business system (built on the logic originally developed for Soule Steel Company).

The new ERP system, Contract Management, is the first rebar software solution to cover Estimating through Contract Billing and Job Costing, handling multiple locations, divisions, and sales locations in a single database.

Contract Management replaces Barker Steel’s proprietary business software along with the Estimating and Tagging software produced by Soule's competitor.

Soule Teleprocessing Corporation is renamed to Soule Software to better reflect the transition from mainframe-based telephone line computing to Windows desktop and server-based solution

Soule Software experiences rapid growth across both the US and Canada as companies of all sizes eagerly adopt the new Contract Management system. The software is translated into additional languages as Soule expands into Europe, the Middle East, and China.

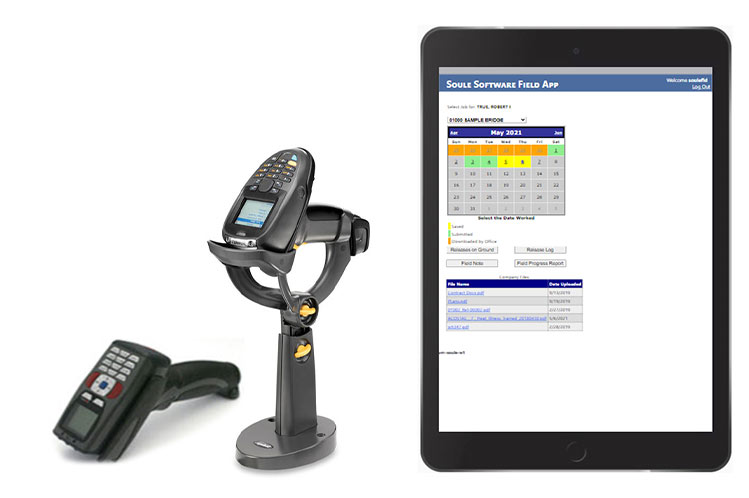

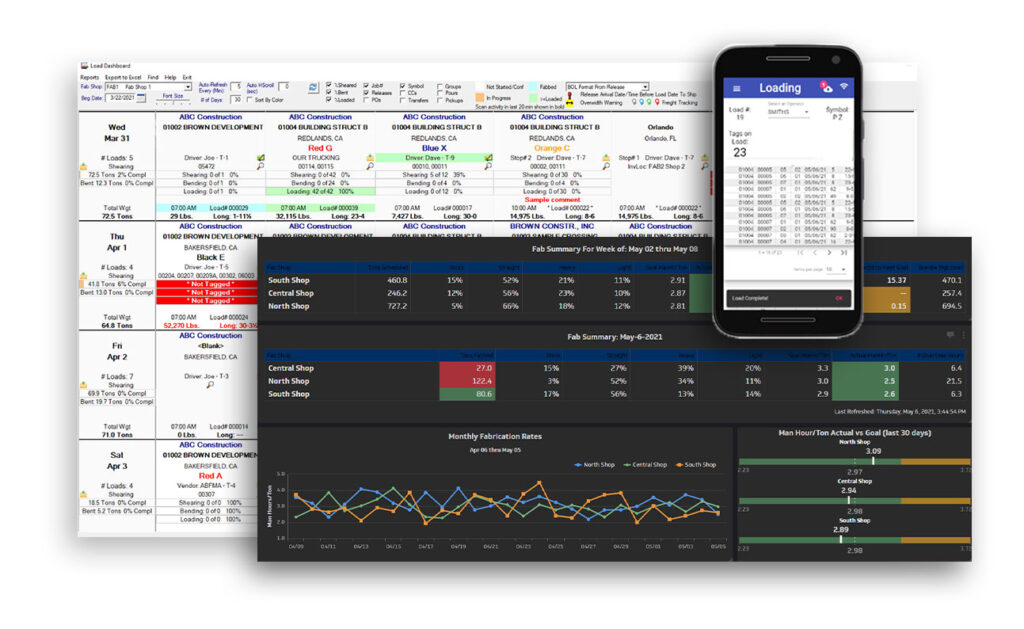

Both the Inventory & Purchase Order module and the Bluetooth barcode scanners are introduced, propelling Soule to become the first to simultaneously track real-time inventory bundle usage and shop productivity across multiple shops.

Soule Software partners with CMC Steel to develop the first web-based Field App to track ironworker timecards and placing activity at job sites. This web-based solution provides management the ability to compare estimated vs actual field productivity on a daily basis.

Soule Software develops the first rebar customer portal where the fabricator’s customers can order rebar online, view the status of their current orders, and even follow their deliveries to them on a map (integrated with the new cell-phone based Freight Tracking system).

The company develops a web-based Fabrication KPI dashboard to display real-time shop productivity across multiple fab plants, displaying actual vs. goal fabrication rates per plant per day based on fabrication schedules.

The Field Placing KPI dashboard is introduced, showing placing productivity across all active jobs through the lifespan of each contract. The Field KPI gives placers the ability to see estimated vs actual placing rates for each type of construction on the job, as well as estimated vs actual crew mix costs. This enables management to have a complete picture of each job, seeing the overall savings or losses job to date, as well as projected savings or losses at contract completion.

In response to their customer’s needs and requests, Soule Software hires additional developers and continues to improve and expand the software modules, releasing on average over 200 new features each year.

Soule Software adopts a new logo which reflects their legacy from the Soule Steel Company.

The company opens an office on the East Coast to better reach their growing customer base.

As Soule Software enters into the next decade of serving the rebar industry, we continue to embrace the innovative development that is a key component of our DNA, spanning back to Edward Soule's humble beginnings at the start of the 20th century.